Driving transformation,

from the wheels up

For nearly 60 years we’ve advanced the commercial vehicle industry with smarter, safer, and more sustainable solutions

An Industry Leader

Our Story

Since 1964 ConMet has been transforming the commercial vehicle industry from the wheels up

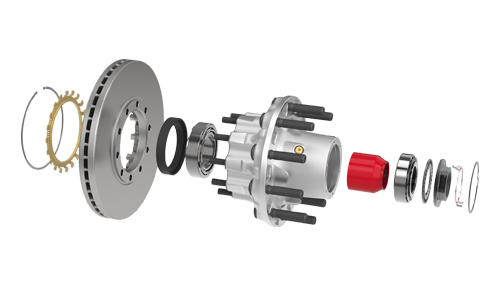

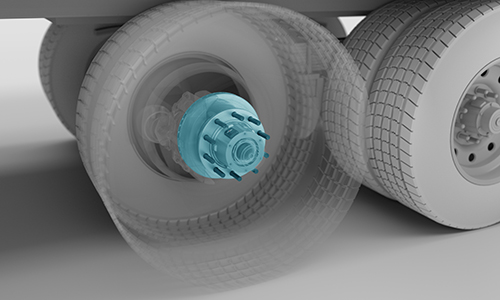

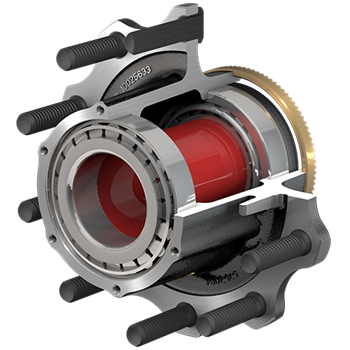

We started at the wheel end, making one of the most critical parts on the truck and trailer lighter, higher quality, and more efficient. Our team of experts crafted the industry’s lightest components through design, testing, and engineering— creating advanced solutions to increase uptime, safety, and efficiency.

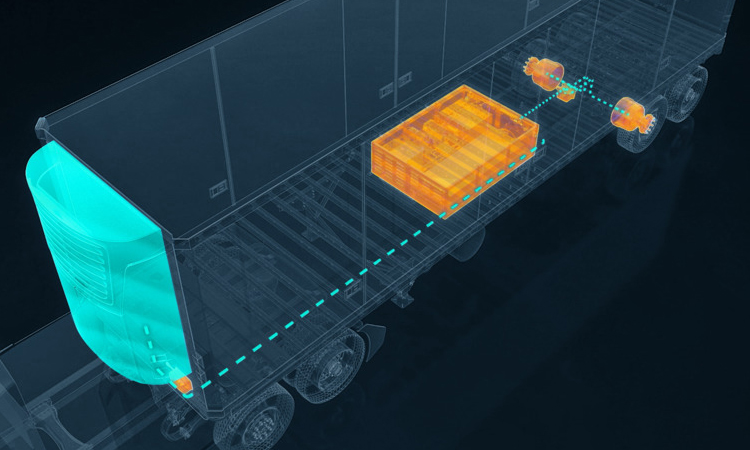

Our commercial vehicle expertise enabled us to expand and innovate across the truck and trailer by offering bespoke plastic and casting component solutions. Today, we support our customers by taking their vision into full-scale manufacturing with the highest precision, quality, and structural integrity.

A force for positive change, creating smarter, safer and more sustainable solutions

As masters of our craft within the heavy-duty industry, we continue to leverage our expertise to innovate electrification and fleet intelligence technologies. We’re reducing emissions, maximizing efficiency, and helping our customers perform more effectively.

We are on a relentless pursuit to imagine and engineer transformative solutions that improve the success of our customers and the lives of our employees. Accomplishing both is how we drive the industry forward.

Our Vision

To become the world’s most trusted solutions provider in the commercial vehicle industry

Our Mission

To improve the lives of our employees, and success of our customers by delivering premium value through innovative solutions

Our Core Values

To focus on customers, promote employee integrity, respect all people, and strive for excellence in all that we do

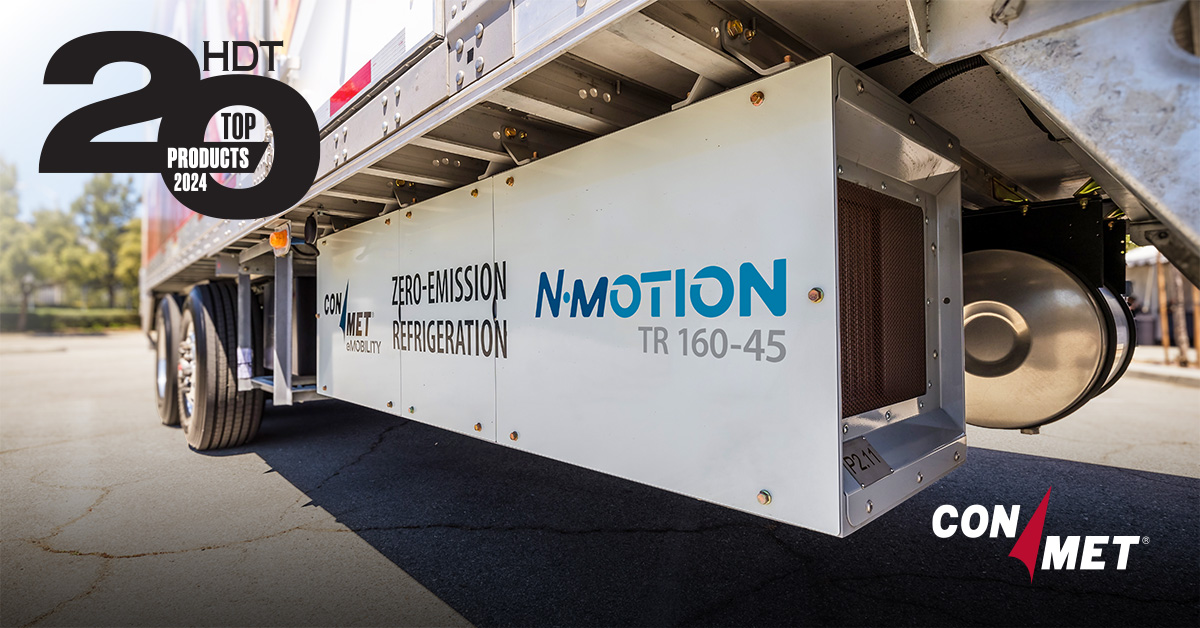

Award-Winning Expertise

Our staunch commitment to consistently delivering innovative, high-quality solutions has been recognized by industry leaders and customers alike, driving us to set new standards and exceed expectations.

Paving the Way for Environmental Sustainability

We are dedicated to developing and utilizing sustainable solutions that reduce our carbon footprint, minimize waste, and enhance the world in which we live.

A Rich Culture of Collaboration and Growth

We actively work to cultivate a company culture centered in innovation and teamwork that unites our global teams in driving our industry forward.

ConMet’s PeopleGlobal Footprint

See ConMet’s local support for customers around the world.

Fueling transformation across our global footprint

Fueling transformation across our global footprint

Fueling transformation across our global footprint

-

Vancouver, Washington

ConMet Corporate Headquarters

-

5701 SE Columbia Way

Vancouver, WA 98661 - +1 360 828 2599

ConMet Technical Center

-

603 SE Assembly Ave., Bldg. 58

Vancouver, WA 98661 - +1 360 699 3023

CNC Machining and Plastic Assembly

-

801 SE Assembly Ave., Bldg. 59

Vancouver, WA 98661

-

5701 SE Columbia Way

-

Clackamas, Oregon

Aluminum Die Cast Solutions

-

10448 Highway 212

Clackamas, OR 97015 - +1 503 657 4183

-

10448 Highway 212

-

Canton, North Carolina

Structural Plastic Components

-

171 Great Oak Dr.

Canton, NC 28716 - +1 828 454 6000

-

171 Great Oak Dr.

-

Monroe, North Carolina

Wheel End Foundry, & Machining

-

Dock Address: 1700 North Charlotte Ave.

Monroe, NC 28110 - +1 828 454 6000

Wheel End Assembly and Warehouse

-

4515 Corporate Center Drive

Monroe, NC 28110 - +1 704 289 6491

-

Dock Address: 1700 North Charlotte Ave.

-

Charlotte, North Carolina

Aftermarket Fulfillment Center

-

13319 Carowinds Blvd.

Charlotte, NC 28273

-

13319 Carowinds Blvd.

-

Denton, Texas

Structural Plastic Components

-

4950 Dakota Lane

Denton, TX 76207

-

4950 Dakota Lane

-

Monterrey, Mexico (ConMet de Mexico)

Structural Plastic Components, Permanent Mold Aluminum Castings, and Wheel End Products

-

Av. Américas 100, Parque Ind. Las Américas

Ciénega De Flores, NL, 65550 - +011 52 818 154 7703

-

Av. Américas 100, Parque Ind. Las Américas

-

Shanghai, P.R.China

ConMet Chinese Headquarters

-

Rm No. 2204 Litong Square,

No. 1350 North Sichuan Road, Post code: 200080

-

Rm No. 2204 Litong Square,

-

Weifang, Shandong Province

ConMet Mechanical Co., Ltd.

-

289 Xihuan Road, Changyi City, Weifang City, Shandong Province, China

Post Code: 261300 - +86 0536 5030666

ConMet (Weifang) Mechanical Co., Ltd.

-

Haoxin Industry Park, Weizi Town, Changyi City, Weifang, Shandong Province, China

Post Code: 261300 - +86 0536 5030666

-

289 Xihuan Road, Changyi City, Weifang City, Shandong Province, China

-

Nanjing, Jiangsu Province

![[18][0]](https://conmet.com/wp-content/uploads/2024/02/COMN_0023.jpg)

ConMet (Nanjing) Mechanical Co., Ltd.

-

No. 58, Yihu Road, Lishui District, Nanjing City, Jiangsu Province, China

Post Code: 211200 - +86 025 6958 6666

-

No. 58, Yihu Road, Lishui District, Nanjing City, Jiangsu Province, China

-

Stuttgart, Germany

ConMet European Headquarters

- Otto-Lilienthal-Str. 5, 71034 Boeblingen, Germany

- +49 172 72 64 036

-

Apeldoorn, Netherlands (ConMet Netherlands B.V.)

In-Wheel Motor Technology

- Boogschutterstraat 1, Floor (Verdieping) 15, 7324 AE Apeldoorn, The Netherlands

Vancouver, Washington

ConMet Corporate Headquarters

-

5701 SE Columbia Way

Vancouver, WA 98661 - +1 360 828 2599

ConMet Technical Center

-

603 SE Assembly Ave., Bldg. 58

Vancouver, WA 98661 - +1 360 699 3023

CNC Machining and Plastic Assembly

-

801 SE Assembly Ave., Bldg. 59

Vancouver, WA 98661

Aluminum Die Cast Solutions

-

10448 Highway 212

Clackamas, OR 97015 - +1 503 657 4183

Structural Plastic Components

-

171 Great Oak Dr.

Canton, NC 28716 - +1 828 454 6000

Monroe, North Carolina

Wheel End Foundry, & Machining

-

Dock Address: 1700 North Charlotte Ave.

Monroe, NC 28110 - +1 828 454 6000

Wheel End Assembly and Warehouse

-

4515 Corporate Center Drive

Monroe, NC 28110 - +1 704 289 6491

Aftermarket Fulfillment Center

-

13319 Carowinds Blvd.

Charlotte, NC 28273

Structural Plastic Components

-

4950 Dakota Lane

Denton, TX 76207

Structural Plastic Components, Permanent Mold Aluminum Castings, and Wheel End Products

-

Av. Américas 100, Parque Ind. Las Américas

Ciénega De Flores, NL, 65550 - +011 52 818 154 7703

ConMet Chinese Headquarters

-

Rm No. 2204 Litong Square,

No. 1350 North Sichuan Road, Post code: 200080

Weifang, Shandong Province

ConMet Mechanical Co., Ltd.

-

289 Xihuan Road, Changyi City, Weifang City, Shandong Province, China

Post Code: 261300 - +86 0536 5030666

ConMet (Weifang) Mechanical Co., Ltd.

-

Haoxin Industry Park, Weizi Town, Changyi City, Weifang, Shandong Province, China

Post Code: 261300 - +86 0536 5030666

![[18][0]](https://conmet.com/wp-content/uploads/2024/02/COMN_0023.jpg)

ConMet (Nanjing) Mechanical Co., Ltd.

-

No. 58, Yihu Road, Lishui District, Nanjing City, Jiangsu Province, China

Post Code: 211200 - +86 025 6958 6666

ConMet European Headquarters

- Otto-Lilienthal-Str. 5, 71034 Boeblingen, Germany

- +49 172 72 64 036

In-Wheel Motor Technology

- Boogschutterstraat 1, Floor (Verdieping) 15, 7324 AE Apeldoorn, The Netherlands

Latest News

Newest development, recognition and success stories from ConMet.

1964

1964

![[18][0]](https://conmet.com/wp-content/uploads/2024/03/TIME_0008.jpg)